Login

Contact

Description

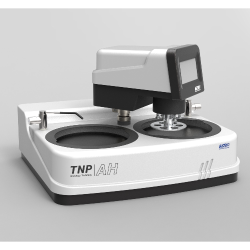

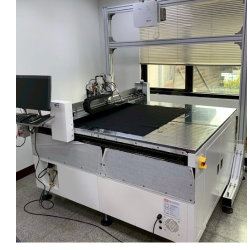

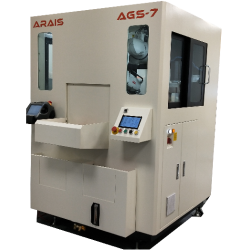

TN-APS Auto Polish System

Pneumatic Polishing Machine

Smart Grinding · Perfect Polishing

The TN-APS is a fully automatic pneumatic polishing machine engineered for high-precision surface treatment applications. Combining innovative design with advanced technology, it delivers high efficiency, consistent stability, and superior polishing quality. Whether used on metals, ceramics, or composite materials, TN-APS ensures exceptional flatness and smoothness in polishing results.

⸻

Key Features

Dual Pressure Modes: Central / Individual Pressing

Precisely controls polishing pressure to suit various specimen shapes and requirements, ensuring uniform processing of every detail.

7-Inch Color Touch LCD Interface

Intuitive user interface with clear display of all parameters and settings, making operation easy and highly efficient.

Automatic Plate-Changing Function

Enables seamless switching between polishing plates, enhancing processing flexibility and production continuity—reducing the need for manual intervention and lowering labor costs.

Oscillating Polishing Design

Simulates manual oscillation to enhance polishing uniformity and prevent center over-polishing or localized surface wear.

⸻

High-Efficiency · Stability · Intelligence

TN-APS is more than just a polishing machine—it is your intelligent partner in precision manufacturing. Ideal for applications such as metals, semiconductor packaging, optical components, and precision molds, it is the optimal solution for manufacturers pursuing automation and high-quality standards.

Pneumatic Polishing Machine

Smart Grinding · Perfect Polishing

The TN-APS is a fully automatic pneumatic polishing machine engineered for high-precision surface treatment applications. Combining innovative design with advanced technology, it delivers high efficiency, consistent stability, and superior polishing quality. Whether used on metals, ceramics, or composite materials, TN-APS ensures exceptional flatness and smoothness in polishing results.

⸻

Key Features

Dual Pressure Modes: Central / Individual Pressing

Precisely controls polishing pressure to suit various specimen shapes and requirements, ensuring uniform processing of every detail.

7-Inch Color Touch LCD Interface

Intuitive user interface with clear display of all parameters and settings, making operation easy and highly efficient.

Automatic Plate-Changing Function

Enables seamless switching between polishing plates, enhancing processing flexibility and production continuity—reducing the need for manual intervention and lowering labor costs.

Oscillating Polishing Design

Simulates manual oscillation to enhance polishing uniformity and prevent center over-polishing or localized surface wear.

⸻

High-Efficiency · Stability · Intelligence

TN-APS is more than just a polishing machine—it is your intelligent partner in precision manufacturing. Ideal for applications such as metals, semiconductor packaging, optical components, and precision molds, it is the optimal solution for manufacturers pursuing automation and high-quality standards.

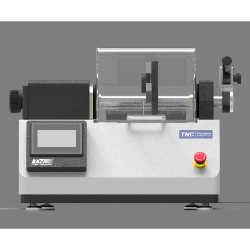

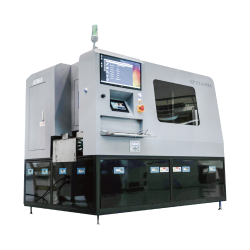

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry