Login

Contact

Description

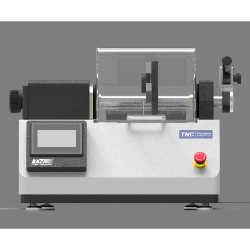

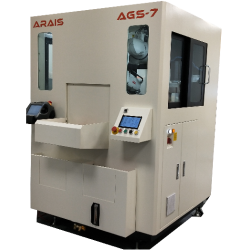

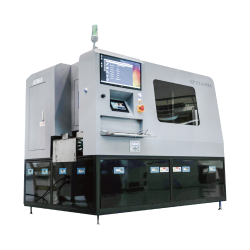

Micro Vickers Hardness Tester with Automatic Indentation Measurement System

This system integrates a high-precision Micro Vickers hardness tester with the AR Series automatic indentation recognition and measurement software. It is specifically designed for evaluating material hardness under micro-load conditions and is ideal for applications such as surface treatment layer analysis, coating inspection, thin film hardness, and heat treatment depth profiling.

With its precise loading mechanism and optical imaging module, combined with advanced software automation, the system delivers highly consistent, accurate, and efficient hardness testing with minimal operator influence.

⸻

Key Features

High-Stability Micro Load Control

Equipped with a precise force application system, supporting test loads from 10 gf to 1 kgf. Suitable for coatings, thin films, and small precision components.

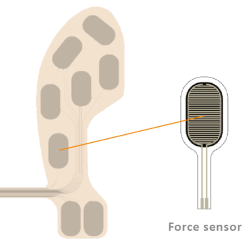

Clear Optical Imaging System

Integrated with high-magnification objectives and a high-resolution camera sensor, ensuring clear visibility of indentation edges for precise measurement.

AR Series Automatic Measurement Software

The AR software features automatic diagonal detection, autofocus, data integration, and multilingual interface (Chinese/English). It simplifies operation while enhancing accuracy.

Data Logging and Report Output

Supports full report export in Excel or PDF format, including indentation images, measurement data, and statistical analysis. Ideal for quality control documentation and traceability.

Versatile Application Fields

Widely used in case depth evaluation of heat-treated parts, electronic component inspection, MEMS and micro-material research, powder metallurgy, and precision manufacturing.

This system integrates a high-precision Micro Vickers hardness tester with the AR Series automatic indentation recognition and measurement software. It is specifically designed for evaluating material hardness under micro-load conditions and is ideal for applications such as surface treatment layer analysis, coating inspection, thin film hardness, and heat treatment depth profiling.

With its precise loading mechanism and optical imaging module, combined with advanced software automation, the system delivers highly consistent, accurate, and efficient hardness testing with minimal operator influence.

⸻

Key Features

High-Stability Micro Load Control

Equipped with a precise force application system, supporting test loads from 10 gf to 1 kgf. Suitable for coatings, thin films, and small precision components.

Clear Optical Imaging System

Integrated with high-magnification objectives and a high-resolution camera sensor, ensuring clear visibility of indentation edges for precise measurement.

AR Series Automatic Measurement Software

The AR software features automatic diagonal detection, autofocus, data integration, and multilingual interface (Chinese/English). It simplifies operation while enhancing accuracy.

Data Logging and Report Output

Supports full report export in Excel or PDF format, including indentation images, measurement data, and statistical analysis. Ideal for quality control documentation and traceability.

Versatile Application Fields

Widely used in case depth evaluation of heat-treated parts, electronic component inspection, MEMS and micro-material research, powder metallurgy, and precision manufacturing.

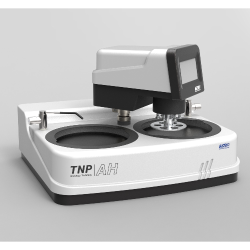

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry