Login

Contact

Description

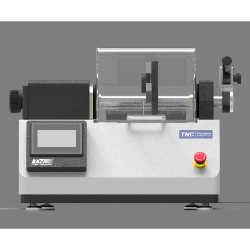

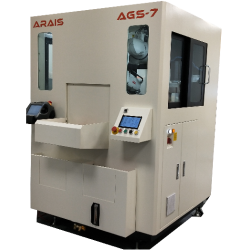

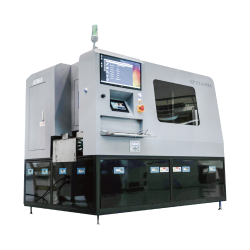

FLV Fully Automatic Load Cell Vickers Hardness Testing System

The FLV Series, developed by FUTURE-TECH Japan, is a fully automatic Vickers hardness testing system that adopts a high-precision load cell mechanism to replace traditional weight-and-lever structures. This ensures more stable and precisely controlled force application. Combined with advanced image recognition and automatic positioning platforms, the FLV Series enables fully automated indentation, alignment, and measurement—ideal for high-precision material research, process monitoring, and quality validation.

⸻

🔧 Key Features

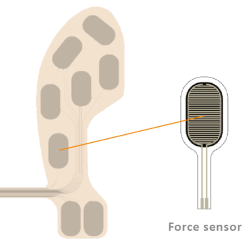

• Load Cell Force Control Technology

Replaces conventional weights and levers with an electronic load cell, delivering accurate force application with fast load switching, multiple load levels, excellent repeatability, and long-term stability.

• Fully Automated Testing Platform

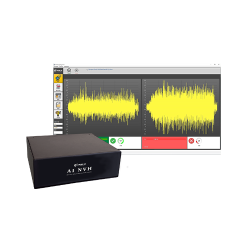

Equipped with autofocus, automatic indentation recognition, and advanced image processing. Supports multi-point hardness mapping, automated data collection, and statistical analysis.

• Multiple Testing Modes

In addition to standard Vickers testing, the FLV Series also supports Knoop hardness, micro-area hardness mapping, and case-hardened depth (CHD) profiling.

• Intuitive Operating Interface

Guided workflow interface simplifies operation and reduces the learning curve for new users.

• Comprehensive Report Output

Test results can be quickly exported in Excel or PDF format, including hardness curves, statistical charts, and annotated indentation images for traceability and documentation.

⸻

Application Fields

• Case Hardened Depth (CHD) Analysis

• Surface Coating and Thin Film Hardness Testing

• Microstructural Gradient Hardness Mapping

• Quality Control of Electronic Materials and Precision Components

• Material Testing in Laboratories and Research Institutes

The FLV Series, developed by FUTURE-TECH Japan, is a fully automatic Vickers hardness testing system that adopts a high-precision load cell mechanism to replace traditional weight-and-lever structures. This ensures more stable and precisely controlled force application. Combined with advanced image recognition and automatic positioning platforms, the FLV Series enables fully automated indentation, alignment, and measurement—ideal for high-precision material research, process monitoring, and quality validation.

⸻

🔧 Key Features

• Load Cell Force Control Technology

Replaces conventional weights and levers with an electronic load cell, delivering accurate force application with fast load switching, multiple load levels, excellent repeatability, and long-term stability.

• Fully Automated Testing Platform

Equipped with autofocus, automatic indentation recognition, and advanced image processing. Supports multi-point hardness mapping, automated data collection, and statistical analysis.

• Multiple Testing Modes

In addition to standard Vickers testing, the FLV Series also supports Knoop hardness, micro-area hardness mapping, and case-hardened depth (CHD) profiling.

• Intuitive Operating Interface

Guided workflow interface simplifies operation and reduces the learning curve for new users.

• Comprehensive Report Output

Test results can be quickly exported in Excel or PDF format, including hardness curves, statistical charts, and annotated indentation images for traceability and documentation.

⸻

Application Fields

• Case Hardened Depth (CHD) Analysis

• Surface Coating and Thin Film Hardness Testing

• Microstructural Gradient Hardness Mapping

• Quality Control of Electronic Materials and Precision Components

• Material Testing in Laboratories and Research Institutes

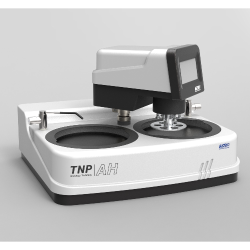

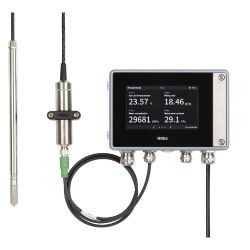

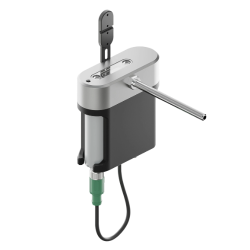

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry