Login

Contact

Description

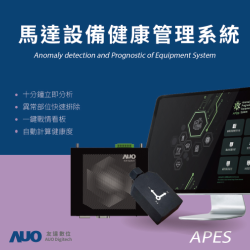

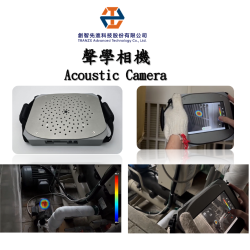

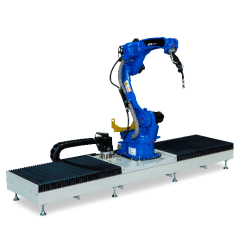

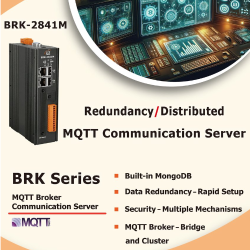

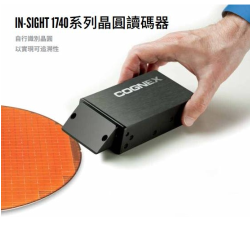

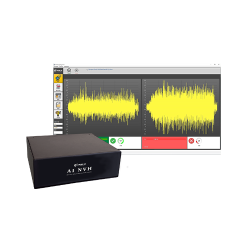

AUO Digitech leverages its Motor Equipment Health Management System to help production lines effectively monitor equipment operation status, reducing reliance on manual inspections and experience-based maintenance. Equipped with intelligent analysis features, the system can complete a comprehensive equipment health assessment within just 10 minutes, while providing real-time abnormality alerts. This allows on-site personnel to quickly identify problem areas and address potential issues in advance, minimizing the risk of unexpected downtime.

In addition, the system’s intuitive dashboard offers clear, visualized insights into the overall health and operational trends of production equipment. This enhances maintenance efficiency and enables a more scientific and data-driven maintenance strategy. With its easy-to-understand health indicators, even non-technical personnel can easily grasp equipment conditions, making the system simple to operate and quick to adopt.

Overall, AUO Digitech’s solution accelerates abnormality detection, reduces maintenance costs, and enhances production line stability—moving toward the goal of zero unplanned downtime.

◎ Shortens abnormality response time

◎ Improves maintenance efficiency

◎ Reduces production downtime risks

In addition, the system’s intuitive dashboard offers clear, visualized insights into the overall health and operational trends of production equipment. This enhances maintenance efficiency and enables a more scientific and data-driven maintenance strategy. With its easy-to-understand health indicators, even non-technical personnel can easily grasp equipment conditions, making the system simple to operate and quick to adopt.

Overall, AUO Digitech’s solution accelerates abnormality detection, reduces maintenance costs, and enhances production line stability—moving toward the goal of zero unplanned downtime.

◎ Shortens abnormality response time

◎ Improves maintenance efficiency

◎ Reduces production downtime risks

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry