Login

Contact

Description

No more blind spots in the digital process

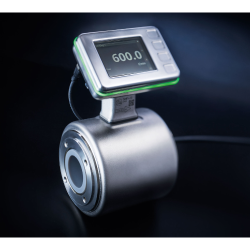

The SM Foodmag magnetic-inductive flow sensor takes the flow measurement of liquid and creamy foods to a new level. Equipped with IO-Link, the sensor is the first of its kind to enable digital data transmission from the process, eliminating the last blind spot in the digitalised, transparent production process. On site, the display itself and the all-round visible status LED provide information on the current status.

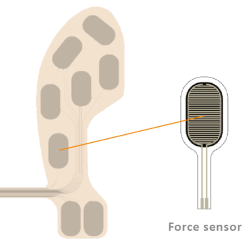

Measures what matters

The sensor detects the current flow rate, total volume and flow direction, as well as the presence of the medium (often referred to as empty pipe detection). It also transmits conductivity and temperature to the control system and IT level. This can reduce the need for additional measuring points in the system.

Convenience, clarity, safety

The integration of the SM Foodmag almost takes care of itself. Combined with our patented cables, the standard M12 connection ensures a fast, waterproof and error-free connection to the data infrastructure. Standard installation dimensions and a flexible choice of seals and process adapters make it easy to integrate into existing systems. The app-based menu structure and guided installation make parameter setting a breeze. Locally and digitally, the SM Foodmag ensures maximum visibility inside the pipe – for greater process reliability.

Extensive internal and external tests ensure from the outset that the SM Foodmag can withstand the extreme conditions of day-to-day processing in the food industry - in the long term.

The temperature shock test puts the sensor’s accuracy to the test when exposed to large temperature fluctuations. These occur during the pasteurisation process, for example, when milk or highly acidic products are heated to between 72 °C and 95 °C and then rapidly cooled down. This process ensures the shelf life of the products. Even after 1,000 hours of continuous stress due to rapid temperature changes from sub-zero to the high double-digit range, the measurement result must still be within the specified accuracy band.

Pumps and valves are required to move the media from the tank to the downstream processing steps. Pumps provide continuous vibration and quick-opening valves for pressure peaks. The pressure peak test simulates the rapid pressure surges by applying a pressure load that deliberately exceeds the pressure rating specified in the data sheet. After one million cycles, the SM Foodmag is tested for leakage. Shock and vibration along the X, Y and Z axes are also intensively simulated over several days to ensure that external influences do not have a significant impact on the performance of the devices.

In the condensation test, a cold medium is passed through the pipe system and sensor - while the ambient temperature is warm. The SM Foodmag is exposed to high humidity and the resulting condensation for several weeks and in different installation positions to ensure that no moisture can penetrate the device.

The SM Foodmag magnetic-inductive flow sensor takes the flow measurement of liquid and creamy foods to a new level. Equipped with IO-Link, the sensor is the first of its kind to enable digital data transmission from the process, eliminating the last blind spot in the digitalised, transparent production process. On site, the display itself and the all-round visible status LED provide information on the current status.

Measures what matters

The sensor detects the current flow rate, total volume and flow direction, as well as the presence of the medium (often referred to as empty pipe detection). It also transmits conductivity and temperature to the control system and IT level. This can reduce the need for additional measuring points in the system.

Convenience, clarity, safety

The integration of the SM Foodmag almost takes care of itself. Combined with our patented cables, the standard M12 connection ensures a fast, waterproof and error-free connection to the data infrastructure. Standard installation dimensions and a flexible choice of seals and process adapters make it easy to integrate into existing systems. The app-based menu structure and guided installation make parameter setting a breeze. Locally and digitally, the SM Foodmag ensures maximum visibility inside the pipe – for greater process reliability.

Extensive internal and external tests ensure from the outset that the SM Foodmag can withstand the extreme conditions of day-to-day processing in the food industry - in the long term.

The temperature shock test puts the sensor’s accuracy to the test when exposed to large temperature fluctuations. These occur during the pasteurisation process, for example, when milk or highly acidic products are heated to between 72 °C and 95 °C and then rapidly cooled down. This process ensures the shelf life of the products. Even after 1,000 hours of continuous stress due to rapid temperature changes from sub-zero to the high double-digit range, the measurement result must still be within the specified accuracy band.

Pumps and valves are required to move the media from the tank to the downstream processing steps. Pumps provide continuous vibration and quick-opening valves for pressure peaks. The pressure peak test simulates the rapid pressure surges by applying a pressure load that deliberately exceeds the pressure rating specified in the data sheet. After one million cycles, the SM Foodmag is tested for leakage. Shock and vibration along the X, Y and Z axes are also intensively simulated over several days to ensure that external influences do not have a significant impact on the performance of the devices.

In the condensation test, a cold medium is passed through the pipe system and sensor - while the ambient temperature is warm. The SM Foodmag is exposed to high humidity and the resulting condensation for several weeks and in different installation positions to ensure that no moisture can penetrate the device.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry