Login

Contact

Description

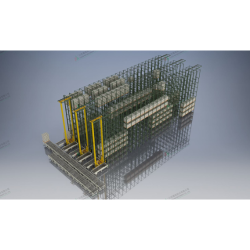

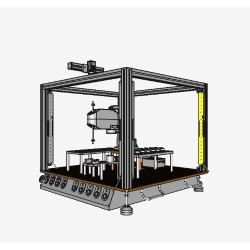

Automatic warehouse AS/RS conveying system, including small type MINI LOAD FOR boxes and cartons, and UNIT/LOAD for pallets.

The 3D design of storage is able to save the space of warehouse.

Equipped with the surrounding conveying system, it saves the time of material handling and able recording and realizes the purpose of automation efficiently and accurately.

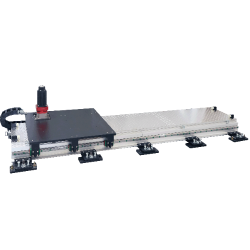

The system includes roller conveyor device, and the PIN UP mechanism matched with AS/RS is used in the outbound/inbound movement.

The transfer mechanism is able to change item’s conveying direction, and the induction unit mechanism for automatic weighing, and the application of the BARCODE READER to read the data.

Automatically read the information of each bin or pallet, it is through the combination between PLC and IPC, and it is actuating to accurate records of the warehousing information.

It can be equipped with displays at each station to display relevant information about the products in and out of the warehouse.

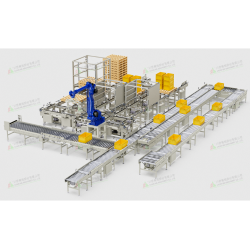

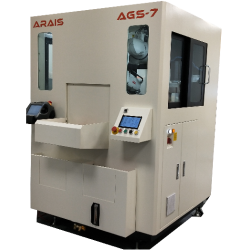

The application of automated stacking uses an automatic stacking pallets machine to unstack the 10-layer pallets in sequence.

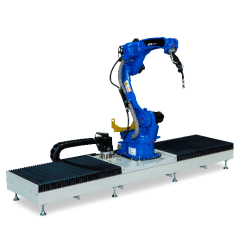

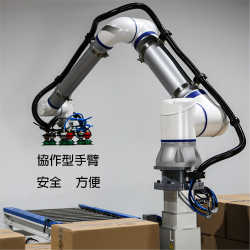

ROBOT arm stacking function is using to stack the set carton or material box on the top of the pallet.

We have fully experiences of applications for the stacking function of major brands ROBOTS and it can set various stacking arrangements with reaching the diversity of product size stacking.

The factory restrictions of the client, we can organize the useful conveying line that also calculating the detailed TACK TIME plus select the optimized transmission mechanism.

For example: RGV (railed guided vehicle) with the design of the FORK type, it is able to transfer pallets to the workstation with in and out of the warehouse which is a significant application example.

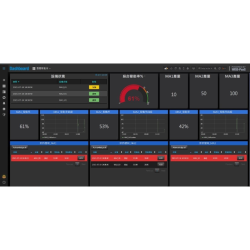

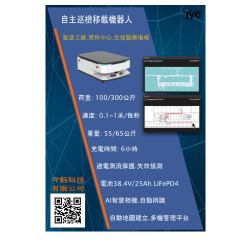

Warehouse management and automated transportation applications can also be used with IOT selection applications, allowing users to obtain detailed warehouse information in time, and achieve the most efficient production management.

The 3D design of storage is able to save the space of warehouse.

Equipped with the surrounding conveying system, it saves the time of material handling and able recording and realizes the purpose of automation efficiently and accurately.

The system includes roller conveyor device, and the PIN UP mechanism matched with AS/RS is used in the outbound/inbound movement.

The transfer mechanism is able to change item’s conveying direction, and the induction unit mechanism for automatic weighing, and the application of the BARCODE READER to read the data.

Automatically read the information of each bin or pallet, it is through the combination between PLC and IPC, and it is actuating to accurate records of the warehousing information.

It can be equipped with displays at each station to display relevant information about the products in and out of the warehouse.

The application of automated stacking uses an automatic stacking pallets machine to unstack the 10-layer pallets in sequence.

ROBOT arm stacking function is using to stack the set carton or material box on the top of the pallet.

We have fully experiences of applications for the stacking function of major brands ROBOTS and it can set various stacking arrangements with reaching the diversity of product size stacking.

The factory restrictions of the client, we can organize the useful conveying line that also calculating the detailed TACK TIME plus select the optimized transmission mechanism.

For example: RGV (railed guided vehicle) with the design of the FORK type, it is able to transfer pallets to the workstation with in and out of the warehouse which is a significant application example.

Warehouse management and automated transportation applications can also be used with IOT selection applications, allowing users to obtain detailed warehouse information in time, and achieve the most efficient production management.

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry