Login

Contact

Description

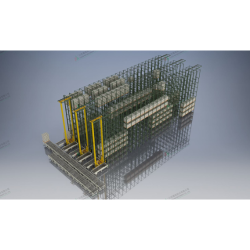

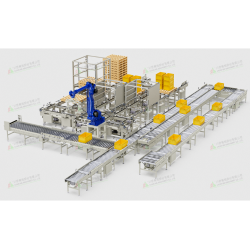

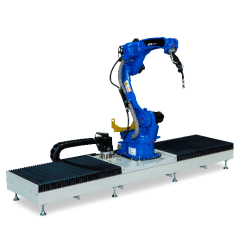

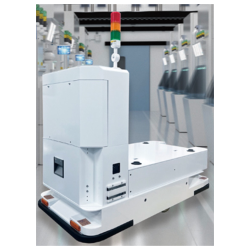

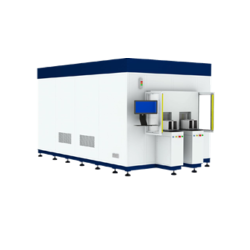

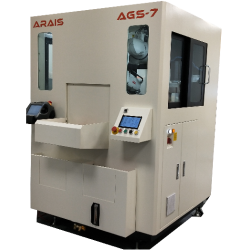

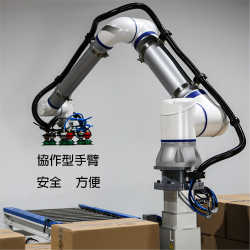

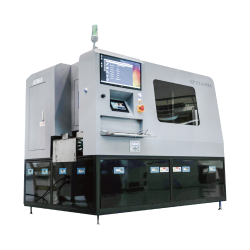

The AGV docking system is a solution that uses the combination of an unmanned guided vehicle (AGV) and a short-stroke elevator to realize automated warehousing and logistics. The AGV can navigate autonomously, lift or tow the trolley from the designated position according to instructions or programs, and transport it to the destination. The trolley can carry different types of goods, such as pallets, boxes, cartons, etc., and seamlessly connect with other equipment such as cranes, conveyors, sorting systems, etc.

Improve efficiency: AGV can reduce the time and cost of manual handling, and improve the flow speed and accuracy of materials.

Space-saving: AGV can use the height of the space for three-dimensional storage and handling, and reduce the idleness and occupation of trolleys.

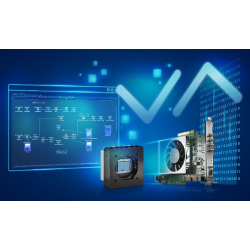

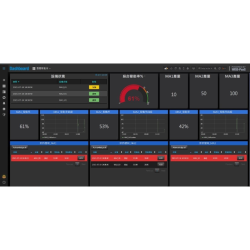

Smart management: AGV can perform dynamic scheduling and real-time monitoring through the central control system and wireless communication, and integrate with upper-level ERP/WMS/MES and other system software to realize digital and intelligent warehousing and logistics management.

Customized or integrated services can be provided according to the needs and field environment, including AGV types, guidance methods, carrying devices, docking equipment, control systems, etc. We have rich experience and a professional team that can create the most suitable AGV pallet docking system for you.

Improve efficiency: AGV can reduce the time and cost of manual handling, and improve the flow speed and accuracy of materials.

Space-saving: AGV can use the height of the space for three-dimensional storage and handling, and reduce the idleness and occupation of trolleys.

Smart management: AGV can perform dynamic scheduling and real-time monitoring through the central control system and wireless communication, and integrate with upper-level ERP/WMS/MES and other system software to realize digital and intelligent warehousing and logistics management.

Customized or integrated services can be provided according to the needs and field environment, including AGV types, guidance methods, carrying devices, docking equipment, control systems, etc. We have rich experience and a professional team that can create the most suitable AGV pallet docking system for you.

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry