Login

Contact

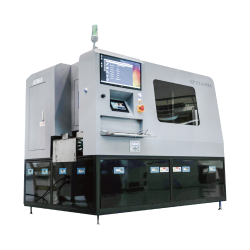

Description

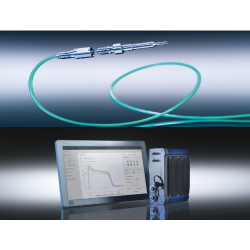

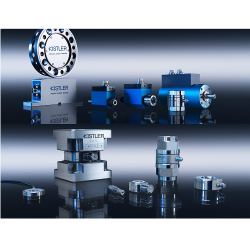

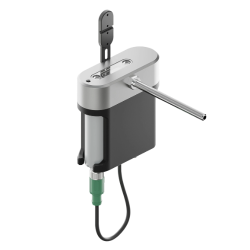

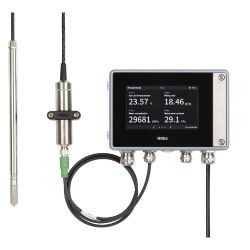

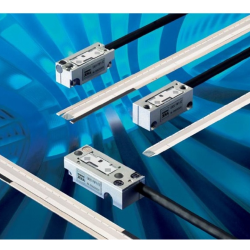

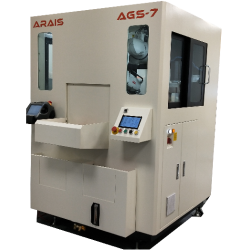

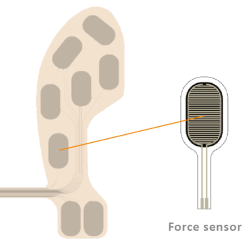

Reliable and accurate sensors are the foundation for effective process monitoring in injection molding. Measuring where the process actually takes place is the key to maximum process transparency. That’s why it’s our philosophy to acquire the critical process values of pressure and temperature directly in the injection mold. Our monitoring systems immediately show any deviations from the ideal state in the relevant process curves, so users can reliably predict the quality of the molded part – shot by shot.

Benefits:

• Efficient and targeted setup phase for new molds

• Minimum time and effort for tool startup

• Reliable monitoring of the injection molding process

• Highly informative individual documentation for each manufactured part

Benefits:

• Efficient and targeted setup phase for new molds

• Minimum time and effort for tool startup

• Reliable monitoring of the injection molding process

• Highly informative individual documentation for each manufactured part

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry