Login

Contact

Description

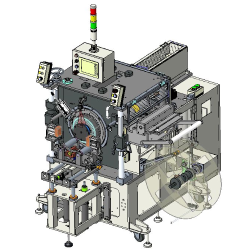

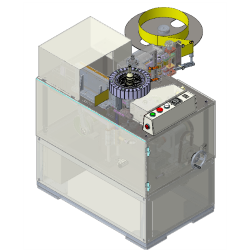

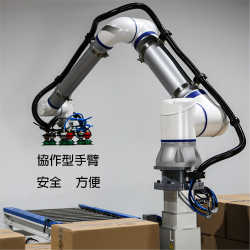

Product applications:

Drilling machine、Grinding machine head、Moving equipment、Conveying positioning、Capping machine、CNC internal & external grinder、Metal feeder、 Automatic fabric inspection machine, etc.

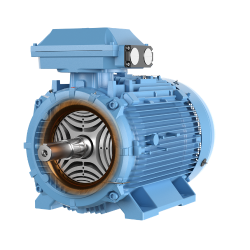

Innovated Matchservo Motor

1. AC servo motor has low noise, minimized EMI and maintenance free.

2. Brushless servo motor is specialized design to have smooth shaft rotation and improved reliability.

3. Servo motors are light weight and compact size, higher power density, higher torque density and higher efficiency than conventional AC motors.

4. A wide range of high-efficiency operation speed 30~3000RPM, suitable for the load changes, speed variation operating conditions are generally advantages that conventional motor can't achieve.

Intelligent Servo Drive Controller

1. The servo driver provides position, speed and torque for three kinds of basic modes operation.

2. Digital I / O output into regulation.

3. Dual system control by torque and speed.

4. Internal servo drive provides 8 segments speed, two-stage acceleration and deceleration control.

5. Internal servo drive 7 segments provides position location, a return HOME mode, eliminate the cumulative amount of error, precise, no need of PC (such as HMI, PLC) control, save costs on PC, and therefore more in line with market demand.

6. Applicable to many commonly used control interfaces such as RS485, standard panel, terminal signal control, PLC and human-peer.

7. Available for all control interfaces, ex. RS 485, direct signal, PLC, HMI.

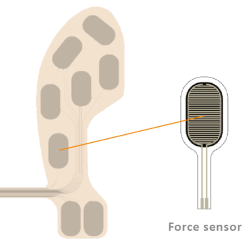

8. Servo drive provides 24VDC for SENSOR require.

9. Speed rendering and real output DC10V for external control header.

10. Servo drive signals can be output 128 PPR for external control using.

11. Position tolerance on high speed, avoid over-current, over-voltage and motor blocked protection against abnormality occurs.

Drilling machine、Grinding machine head、Moving equipment、Conveying positioning、Capping machine、CNC internal & external grinder、Metal feeder、 Automatic fabric inspection machine, etc.

Innovated Matchservo Motor

1. AC servo motor has low noise, minimized EMI and maintenance free.

2. Brushless servo motor is specialized design to have smooth shaft rotation and improved reliability.

3. Servo motors are light weight and compact size, higher power density, higher torque density and higher efficiency than conventional AC motors.

4. A wide range of high-efficiency operation speed 30~3000RPM, suitable for the load changes, speed variation operating conditions are generally advantages that conventional motor can't achieve.

Intelligent Servo Drive Controller

1. The servo driver provides position, speed and torque for three kinds of basic modes operation.

2. Digital I / O output into regulation.

3. Dual system control by torque and speed.

4. Internal servo drive provides 8 segments speed, two-stage acceleration and deceleration control.

5. Internal servo drive 7 segments provides position location, a return HOME mode, eliminate the cumulative amount of error, precise, no need of PC (such as HMI, PLC) control, save costs on PC, and therefore more in line with market demand.

6. Applicable to many commonly used control interfaces such as RS485, standard panel, terminal signal control, PLC and human-peer.

7. Available for all control interfaces, ex. RS 485, direct signal, PLC, HMI.

8. Servo drive provides 24VDC for SENSOR require.

9. Speed rendering and real output DC10V for external control header.

10. Servo drive signals can be output 128 PPR for external control using.

11. Position tolerance on high speed, avoid over-current, over-voltage and motor blocked protection against abnormality occurs.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry